SLIPNOT Technology

Transforming ordinary flooring and surfaces into confident, slip resistant workspaces

High performance technology

SLIPNOT performance technology is a multi-step engineering surface preparation and modification process, applied in our factory-controlled environment in Detroit, Michigan.

Our technology creates an unparalleled bond to metal, creating a high-friction surface that eliminates over 90% of slips and falls, even with the toughest oil, chemical and water spills. It’s durable, long-lasting, grit-free and FDA compliant. That means reduced operating expenses and downtime, fewer lost workdays, and a more engaged and confident workforce.

Our experts will guide your selection based upon your unique environment and application. We can customize to your specific surface and installation requirements through a variety of alloys, colors and finishes.

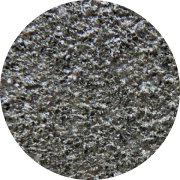

The steel SLIPNOT surface can be applied to steel or aluminum substrates. Applying steel to aluminum combines the lightweight properties of aluminum and the file hard surface of steel. SLIPNOT steel products are used in manufacturing industries where oil is present, among other diverse industries. The alloy is used for stairs, platforms, ladders, trench covers, road plates, conveyor lines and various other applications. Our steel coating is the coarsest surface available and ideal for high traffic areas where viscous liquids are prevalent, such as oil.

Stainless Steel

Stainless steel SLIPNOT can be applied to stainless steel or aluminum substrates. Our stainless steel on aluminum allows for a lightweight material and a chemical and corrosion resistant surface. SLIPNOT stainless steel remains completely slip resistant in countless environments, from food processing plants on catwalks, stairs, drain covers and platforms to walkways and stairs in public recreation areas, corporate offices and educational campuses. Our stainless steel products are registered by NSF International for use in food processing facilities and are used by companies such as Kraft, Tyson Foods, Nestle and many more. In addition to being chemical and corrosion resistant, stainless steel is aesthetically pleasing, versatile and ideal for commercial applications.

Aluminum

The aluminum surface is completely grit-free and is the ideal choice for projects where rust is a concern and that require a lightweight material. SLIPNOT aluminum products also provide a high strength-to weight ratio and are easily fabricated to project requirements. The aluminum surface is only applied to aluminum products and utilized in the aerospace, water/wastewater, utility and government industries, among many other industries. Floating docks, tank covers, walkways, access hatches, catwalks, defense vehicles and countless other applications require slip resistant aluminum products.

Grade 1 – Fine

The Grade 1 (Fine) surface has an average peak to valley surface depth of 0.010” – 0.012”.

This grade is used in light duty applications or areas where a minimum surface roughness is desired. This surface produces the same high coefficient of friction as our Grade 2 (Medium). Any surface treatments, such as priming or painting, should not exceed 5 mils to prevent degradation of the SLIPNOT performance. Hot dipped galvanizing is not available for Grade 1 steel plates.

Grade 1 (Fine) is available for all SLIPNOT surfaces.

Grade 2 – Medium

This surface grade is applicable for nearly every situation. With an average peak to valley surface depth of 0.020”-0.025”; Grade 2 (Medium) SLIPNOT provides maximum traction, durability and longevity.

Surface treatments to this grade should not exceed a total of 10 mils to prevent reduction of the surface coefficient of friction. For steel plates, hot dip galvanizing is the ideal surface protection.

The Grade 2 (Medium) is available for all SLIPNOT surfaces.

Grade 3 – Coarse

This surface is used in the most demanding environments. With an average peak to valley surface depth of 0.032”-0.038”.

This grade provides maximum durability and longevity. For extremely high traffic or highly contaminated environments, Grade 3 (Coarse) SLIPNOT provides maximum traction. Hot dipped galvanizing is the ideal surface protection for steel.

Grade 3 (Coarse) is only offered in our steel SLIPNOT surface. Not available in aluminum and stainless steel surfaces.

SLIPNOT is produced in a standard mill finish. There are no additives or paints applied to the product besides the slip resistant coating. Mill finish will be the raw material color.

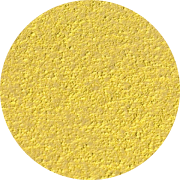

Painted

SLIPNOT products can be painted with a water-based paint, however, care must be taken so the slip resistant properties of the surface are not compromised. Paint is available in black, safety yellow or customized to fit job specifications.

Powder Coated

Powder coating has evolved as a popular dry finishing process used as a protective layer on metal products. It is becoming the preferred finish over traditional painting, providing durability and resistance to corrosion, chemicals, and weather elements. Unlike wet paint, powders don’t run or drip, providing a more uniform coating. The vibrancy of powder coated parts tend to stay bright and fresh longer than wet paint.

Galvanized

SLIPNOT steel products can be offered with a hot-dipped galvanized finish to prevent corrosion. Galvanizing is performed in accordance with ASTM A123 or other appropriate specifications. SLIPNOT steel material can be galvanized after additional fabrication or processing. Please see our Guidelines for Galvanizing SLIPNOT.

Technical information

3 Part Spec & CAD Details

SLIPNOT products can be easily incorporated into any project or specification. The SLIPNOT CSI 3 part specification is provided based on The Construction Specifications Institute format.

Standards & Test Results

SLIPNOT products far exceed ALL standards and recommended guidelines for slip resistance. Certified independent laboratories have tested our products.

Approvals & Certifications

SLIPNOT is an ISO 9001:2015 Registered Company, registered by NSF International for use in food processing and registered slip resistant with Underwriters Laboratories per the UL 410.

Fabricating Instructions

Fabrication is best performed prior to SLIPNOT surface application. SLIPNOT does not recommend any fabrication of products after galvanizing.

Galvanizing Guidelines

Care must be taken in the pickling portion of the hot dipped galvanizing process as the SLIPNOT surface may lift off if pickling times exceed recommendations.

Care & Cleaning

Our products can be cleaned by most standard agents. Clean slip resistant products on a regular basis to prevent any build-up or residue that can cause the peaks and valleys to smooth over.