Think Like a CFO: Speaking to the C-Suite About Safety Spending

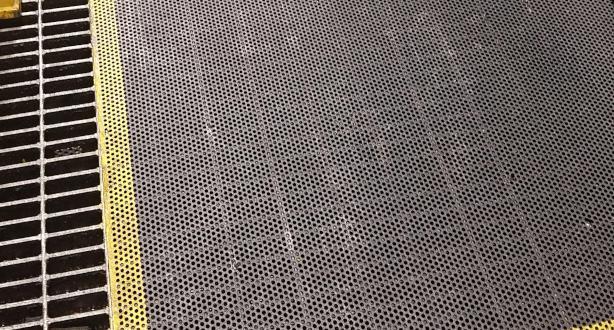

Safety modifications and improvements cost money. Where will those resources come from? Safety leaders must convince the company that installing safe, non-slip technologies on floors, ladders, stairs, and other risky areas is a good long-term investment. This can be challenging for plant engineers, managers, and safety leaders, who are trying to communicate risk and return