Introduction

In industrial and public infrastructure, slip-resistant flooring is essential for safety, efficiency, and regulatory compliance. Facilities that experience foot traffic, exposure to liquids, or heavy equipment movement require flooring solutions that minimize the risk of slips and falls. Proper flooring not only protects workers and the public but also reduces liability risks and potential downtime due to accidents.

There are a multitude of products on the market that claim to provide slip resistance, with varying levels of success. The keys to a useful slip resistant product are how well it works in all environments and how long it lasts.

Comparative Performance Analysis

Understanding Coefficient of Friction (COF) and Testing

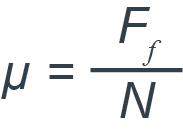

The coefficient of friction (COF) measures how much resistance a surface provides against slipping. A higher COF indicates better traction and is a handy way of comparing how effective a surface will be in preventing slip-and-fall accidents.

To calculate the COF, also known as µ, take the frictional force and divide it by the normal force N.

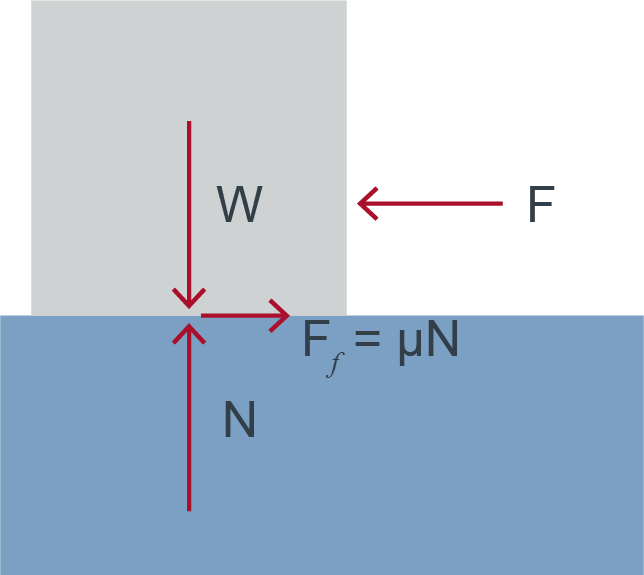

COF Testing and NFSI B101.3 Standard

The National Floor Safety Institute (NFSI) B101.3 standard is used to test the dynamic coefficient of friction (DCOF) of a wet surface, which assesses slip resistance when an object is in motion. The static coefficient of friction (SCOF) is measured between objects not yet in motion. The SCOF in these scenarios is larger than the DCOF, meaning it takes more force to start moving something than it does to keep it sliding.

The DCOF of a wet surface is going to represent a commonly occurring “worst case” scenario with a lower amount of traction. The flooring still needs to provide sufficient traction in this condition to prevent accidents.

The DCOF in this test is determined using a calibrated tribometer to measure the friction between a specified SBR rubber pad and the flooring material. Testing involves wetting the surface with a 0.1% solution of Sodium Lauryl Sulfate (SLS) in distilled water, then applying a controlled horizontal force and measuring the resistance to sliding.

The American National Standards Institute (ANSI) along with the National Floor Safety Institute (NFSI) have developed a chart identifying high-friction and low-friction products based upon their wet dynamic coefficient of friction. Under ANSI’s specification A137 and NFSI B101.3-2022 testing method, a minimum wet DCOF value of 0.42 or higher is required for level interior spaces. For areas exposed to significant water, industrial spaces, areas exposed to oils and grease, etc., a minimum wet DCOF value of 0.60 or higher is required. For ramps and stairs, a minimum wet DCOF of 0.65 or higher is needed.

Following these minimum standards is critical to increasing safety and preventing accidents.

COF Data: SLIPNOT vs. Diamond Tread Plate

The NFSI B101-3 test protocol covers wet dynamic COF, however both static and dry COF readings are included below to show a comprehensive safety assessment. The SLIPNOT and diamond tread plate samples tested are new, without wear.

Fig 2. SLIPNOT Stainless Steel vs Diamond Tread Plate COF Test Results

SLIPNOT maintains a DCOF above 0.8 when wet, which is above the required 0.6 from ANSI and NFSI. Diamond tread plate drops to a DCOF under 0.3, which is dangerously unsafe.

New SLIPNOT is an effective solution for any location that requires reliable slip resistance. The next question then is how long does it last? There are slip resistant products such as tape that can be effective temporarily but might not even last a single work shift in some conditions.

Even after an accelerated wear test simulating 8-16 years of typical workplace traffic, SLIPNOT still retains its required traction. This durability ensures that facilities using SLIPNOT receive a long-term slip-resistant solution that maintains its effectiveness even under wet or oily conditions. Unlike temporary traction solutions that degrade quickly, SLIPNOT’s high-friction surface remains intact and reliable, reducing the need for costly frequent replacements and ongoing maintenance.

The Advantages of SLIPNOT Stainless Steel Flooring

- Superior Traction: Engineered for consistent grip in dry, wet, and oily conditions

- Safety Benefits: Reduced slip-and-fall incidents, leading to happier, more productive workers and lower liability risks

- Productivity Benefits: Workers are more efficient with consistent, sturdy footing

- Durability: Resistant to wear, maintaining high traction properties over time

- Low Maintenance: Corrosion resistant. No need for frequent resurfacing or expensive replacements, reducing long-term upkeep costs.

- Customization Options: Highly adaptable for various industrial and commercial applications

Conclusion

SLIPNOT surfaces are safer for longer: their superior traction and durability ensure long-term performance in both high-risk and everyday environments. For industries prioritizing safety, durability, and long-term value, SLIPNOT products are the clear choice over traditional diamond tread plate.